Advanced Industrial Dehumidification: Enhancing Operations and Safety

Table of Contents

• Industrial Climate Solutions: Desiccant Technology for Precise Dew Point Control

• Core Dehumidification Technologies

• Benefits and Strategic Importance

• Key Industrial Applications

– Heavy Industry & Construction

– Industrial Process Cooling

– Manufacturing & Storage Facilities

– Food Processing & Preservation

– General Industrial Applications

• Partner with Minex for Expert Climate Control

Industrial Climate Solutions: Desiccant Technology for Precise Dew Point Control

Effective humidity control is a decisive factor in today’s industrial landscape, shaping operational reliability, product quality, and compliance with safety standards. Excess moisture or water vapour can cause coating failures, accelerated corrosion, and material degradation - issues that directly impact production and profitability.

A robust industrial dehumidification system, built with specialised technology, helps maintain stable environmental conditions by regulating the dew point, preventing condensation, and continuously monitoring key parameters such as moisture levels and relative humidity (RH). By effectively removing water vapour from the air, these systems ensure optimal operation and improved energy efficiency, even under fluctuating climatic conditions.

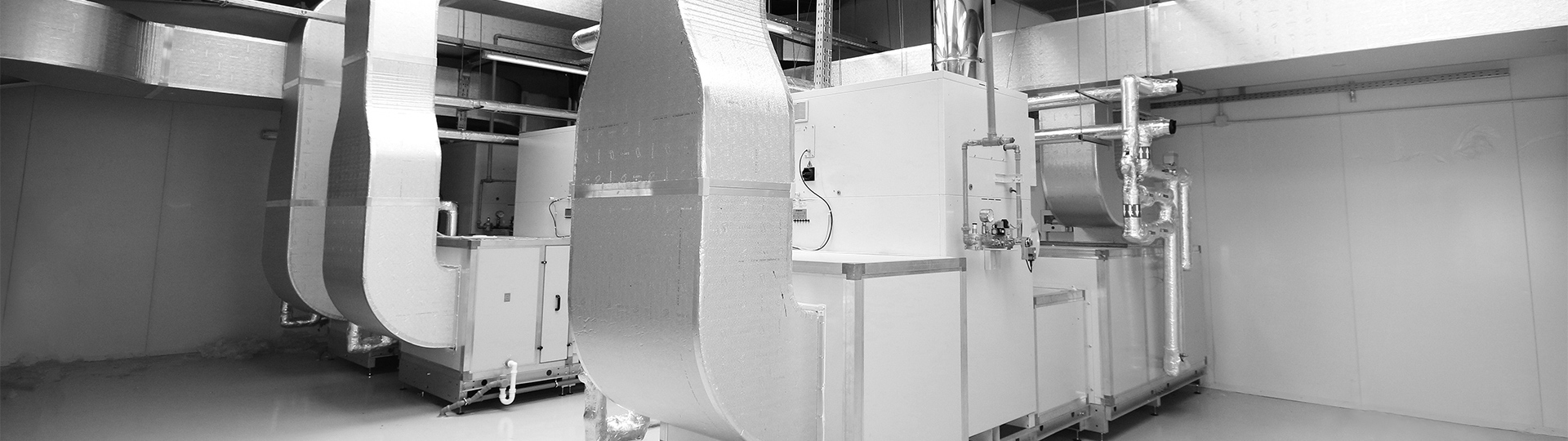

Minex industrial dehumidification systems are designed to ensure dependable climate control in demanding industrial environments. The MNX AH Dehumidifiers and Cooling Groups provide precise humidity and temperature regulation for large-scale production, storage, and commercial facilities, combining durability, safety, and energy-efficient performance.

Core Dehumidification Technologies

Our climate-control portfolio is anchored by two high-performance, complementary technologies engineered for continuous operation:

- MNX AH Desiccant Dehumidifiers - Designed for robust industrial application, these units combine durable construction with efficient, desiccant-based moisture removal. This non-refrigerant process uses a rotating silica gel wheel to adsorb water vapor, achieving precise and ultra-low dew point control. This makes them ideal for environments demanding sub-zero dew points. Their robust metallic frames facilitate rapid deployment and relocation via crane or forklift. System capacity is accurately quantified by airflow (in cubic metres per hour), a critical metric for engineers matching the system precisely to the required process volume.

- Cooling Groups - An integrated chiller and water-to-air heat exchanger that produces chilled water within a stable range of 6∘C to 11∘C. This system provides the essential thermal management necessary for energy-efficient dehumidification and process cooling. Its primary function is to lower the dew point of the air, thereby preventing condensation on sensitive machinery and ensuring stable surface temperatures. Precision temperature regulation is paramount for optimising the moisture removal process.

The combined synergy of desiccant dehumidification and precision cooling ensures a continuous supply of dry air, streamlining the production process by strictly maintaining target environmental specifications.

Benefits and Strategic Importance

As mentioned, effective humidity control is essential for multiple industrial processes, and asset protection, preventing corrosion, moisture-related damage, and the degradation of raw materials. This ensures consistent product quality and reliable equipment performance. Resulting environmental stability significantly reduces maintenance costs, extends asset life, and improves operational safety across the facility.

Furthermore, modern desiccant dehumidifiers contribute to significant energy savings by actively minimising consumption during the moisture extraction process. With precise humidity control and thermodynamic properties specifically optimised for industrial applications, these systems deliver long-term durability and measurable Return on Investment (ROI).

Key Industrial Applications

Heavy Industry & Construction

- Typical Use: Shipyards, fabrication halls, and surface-preparation zones.

- Focus: Controlling high humidity levels during blasting and coating is essential to prevent corrosion and coating failure. The MNX AH Dehumidifiers stabilise the dew point and deliver clean, dry air for optimal surface treatment.

- Benefits:

- Reliable humidity control for surface operations.

- Safe, heavy-duty performance in harsh industrial environments.

- Reduced risk of condensation and coating defects.

Industrial Process Cooling

- Focus: Continuous manufacturing processes require constant temperature and humidity balance. The Cooling Groups ensures process stability, using condensation process to extract water from the process air, controlling the dew point to prevent condensation and excess humidity.

- Benefits:

- High cooling capacity for intensive industrial applications.

- Improved energy efficiency and reduced energy consumption.

- Reliable operation with minimal maintenance.

Manufacturing & Storage Facilities

- Focus: Large facilities demand stable humidity levels to protect goods and infrastructure. Integrated dehumidification systems maintain ideal environmental conditions, preventing mold, ice building, and condensation.

- Benefits:

- Balanced temperature and relative humidity.

- Energy-efficient long-term operation.

- Extended lifespan of stored materials and equipment.

Food Processing & Preservation

- Focus: Maintaining clean, controlled environmental conditions is vital to prevent mold growth, and ice build up. The MNX AH Dehumidifiers and Cooling Groups work together to provide precise control of moisture levels, temperature, and air quality - with glycol-mixture circulation for low-temperature performance.

- Benefits:

- Hygienic climate control with accurate humidity management.

- Reliable operation in cold-storage facilities.

- Compliance with food-safety standards.

General Industrial Applications

- Focus: Reliable industrial dehumidifiers protect sensitive components such as printed circuit boards and control systems from excess moisture and uncontrolled humidity. MNX units include built-in alarms for rotor movement, filter clogging, and electrical phase errors, plus automatic heating shutdown and continuous drainage for safe operation.

- Benefits:

- Safe, automated dehumidification system.

- Improved air quality through high-efficiency G4 filters.

- Reduced downtime and maintenance costs.

Partner with Minex for Expert Climate Control

Selecting the right industrial dehumidification system is key to protecting equipment, optimising energy usage, and achieving consistent performance.

At Minex, we help engineers, operations teams, and procurement managers choose and configure energy-efficient, durable systems for any industrial application - from surface preparation to cold storage facilities and process cooling. We ensure your configuration is designed for durability, safety, and measurable energy efficiency.

Contact us to discuss your industrial dehumidification or cooling requirements and receive a tailored configuration.

Frequently Asked Questions on Industrial Dehumidification

Why is industrial dehumidification important in heavy industry and manufacturing?

Industrial dehumidification plays a vital role in surface treatment applications preventing corrosion, coating defects, and material degradation caused by excess moisture. Maintaining stable humidity levels enhances safety, product quality, and ensures compliance with regulatory standards in industrial settings.

How do desiccant dehumidifiers work in industrial environments?

Desiccant dehumidifiers use a rotating silica gel rotor to adsorb moisture from the air, providing precise dew point control even in sub-zero environments. This technology is essential for removing excess moisture in shipyards, warehouses, food processing facilities, and other commercial spaces.

What is the role of cooling systems in industrial dehumidification?

Cooling systems lower the dew point and stabilise air temperatures, preventing condensation on sensitive machinery. By efficiently removing moisture from the air, they support continuous operations while improving energy efficiency and reducing operational costs.

How do dehumidifiers improve coating and surface preparation quality?

By stabilising humidity and dew point during blasting and coating processes, industrial dehumidifiers keep surfaces dry, prevent flash rust, and ensure durable adhesion, ultimately enhancing the final product quality.

What are the energy-efficiency advantages of modern dehumidification systems?

Modern desiccant dehumidifiers and integrated cooling groups minimise energy consumption through optimised thermodynamic properties and precise moisture removal. These improvements lead to significant energy savings and lower operational costs.

How should engineers select the right industrial dehumidifier?

Choosing the appropriate system involves considering airflow volume (measured in cubic feet or cubic metres per hour), required dew point, ambient temperature, and process sensitivity. Proper selection ensures effective moisture removal and consistent performance.

What safety features are built into Minex dehumidifiers?

Minex industrial dehumidifiers include built-in alarms for rotor movement, filter clogging, and electrical phase errors. Features like automatic heater shutdown, continuous drainage, and high-efficiency air filters promote safe, reliable, and continuous operation.

How does humidity control extend equipment and asset lifespan?

By removing excess moisture and preventing condensation, industrial dehumidification protects machinery and raw materials from corrosion and moisture-related damage, reducing maintenance costs and downtime.

Can industrial dehumidifiers be relocated between facilities or projects?

Yes. MNX AH units are designed with robust metallic frames for easy handling by crane or forklift, allowing quick relocation to meet seasonal changes or shifting operational needs across different industrial settings.