Precision Surface Preparation for Reliable, Safe, and Long-Lasting Results

Precision Surface Preparation for Reliable, Safe, and Long-Lasting Results

Industrial flooring systems must withstand extreme temperatures, constant mechanical stress, and strict hygiene or safety requirements. Effective floor processing - including shot blasting, grinding, and scarifying - ensures uniform adhesion, structural integrity, and a durable finish that performs under heavy industrial conditions. When concrete floors and processing plant surfaces are properly prepared, every subsequent layer - from epoxy coatings to sealants - performs better and lasts longer.

Table of Contents

- A Complete Guide to Industrial Floor Processing

- Grinding Machines for Surface Preparation and Finishing

- Floor Blasting Systems for Large-Scale Surface Renovation

- Scarifying Machines for Heavy Surface Removal

- Dust Extraction Systems for Safety and Compliance

- Partner with Minex for Expert Floor Processing Guidance

A Complete Guide to Industrial Floor Processing

High-quality floor processing forms are the foundation of durable and compliant industrial surfaces. Whether restoring concrete floors, removing epoxy coatings, or preparing substrates for new coverings, precision and consistency are essential.

The equipment in the Minex portfolio - shot blasting machines, grinding systems, and scarifiers - is engineered for heavy-duty use, resisting chemical exposure, thermal stress, and mechanical wear. Each system ensures controlled material removal and reliable results across projects.

Proper surface preparation prevents coating failure, improves adhesion, and extends service life. Selecting the right machine type for each operation increases productivity, reduces downtime, and supports long-term maintenance efficiency.

When planning projects, engineers should assess drainage, load resistance, and cleanability - all key factors influenced by how the floor surface is prepared.

Applications Across Industries

Shot blasting, grinding, and scarifying are essential in industries where surface quality, hygiene, and mechanical resistance are critical. Equipment robust design allow consistent performance under demanding conditions.

- In construction and renovation, shot blasting prepares concrete floors for epoxy coatings, tiles, or other finishes by removing adhesives, paint, and surface contaminants. The result is a clean, uniform surface that promotes strong adhesion and long-term durability.

- In food and beverage processing plants, efficient floor processing ensures hygiene and sanitation by removing residues and bacteria from concrete and metal surfaces. This makes floors easier to clean and compliant with food-industry regulations.

- In manufacturing, grinding and shot blasting prepare steel and metal substrates for coating or painting by eliminating rust and impurities, improving surface texture and resistance to acids, wear, and mechanical stress.

These technologies are also used in aerospace, automotive, and pharmaceutical environments where uniformity, precision, and traceability are essential.

Grinding Machines for Surface Preparation and Finishing

Grinding is the most versatile method in floor processing, suitable for concrete, screed, asphalt, wood, steel, and stone. It provides accurate material removal and smooth, level surfaces ready for coating or polishing.

Tool selection determines performance. The right combination of discs and accessories transforms a grinder into a multi-purpose system for polishing, texturing, or roughness control. Ergonomic design and vibration-damped chassis improve safety and precision during extended work periods.

When to Choose Grinding Machines

- Renovation or preparation of concrete floors, screed, or asphalt.

- Applications requiring high surface flatness or defined texture.

- Final finishing before coating or painting.

Key Benefits

- Controlled material removal prevents damage.

- Adaptable to multiple materials and finishing types.

- Ergonomic design reduces operator fatigue.

- Improves process efficiency and consistency.

Floor Blasting Systems for Large-Scale Surface Renovation

For large industrial floors, mechanical shot blasting is the most efficient method for cleaning and preparing concrete surfaces. It combines high coverage and uniform texturing with minimal cleanup requirements.

This approach is ideal for processing plants, warehouses, and civil engineering projects where surface adhesion and anti-slip properties are essential. Blasting machines remove coatings, roughen smooth surfaces, and create defined adhesion profiles for epoxy coatings or overlays.

When to Choose Floor Blasting Machines

- Large-scale floor renovation or resurfacing.

- Projects requiring consistent surface texture or anti-slip profiles.

- Industrial or civil engineering operations.

Key Benefits

- High productivity with consistent results.

- Reduced preparation time across extensive floors.

- Rugged design built for long-term industrial use.

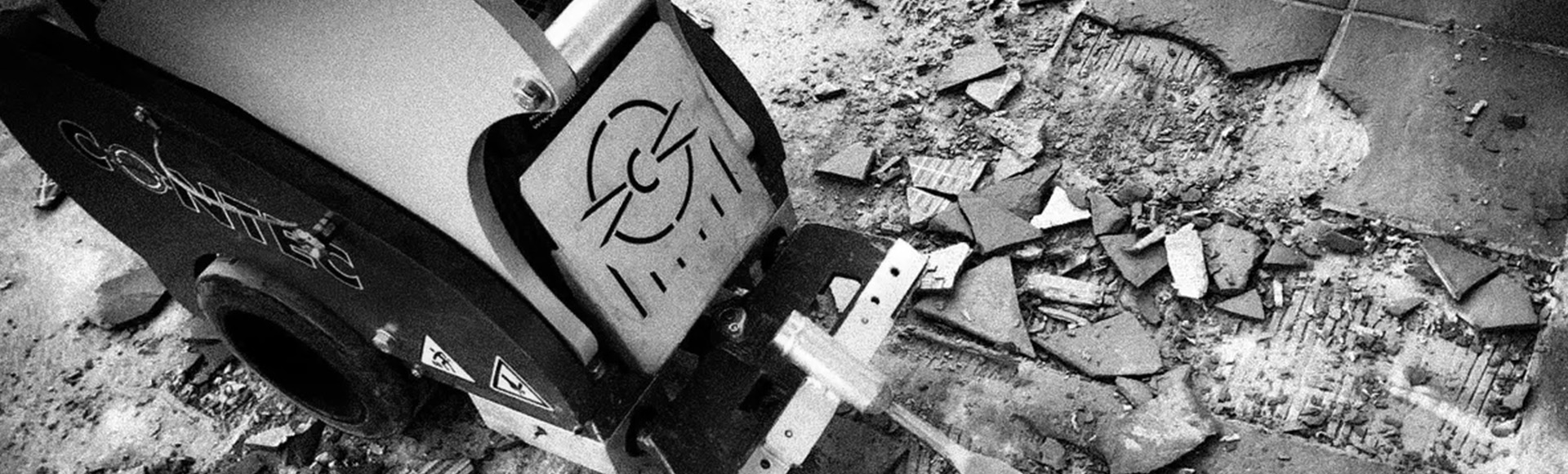

Scarifying Machines for Heavy Surface Removal

Scarifying provides aggressive removal of coatings, adhesives, and damaged concrete. Rotating cutting tools create rough, non-slip textures ideal for overlays or resurfacing.

Scarifiers are widely used for industrial and outdoor floors that require deep material removal or preparation for anti-slip treatments. Adjustable cutting depth and feed rate enable precise control and efficient results across a variety of materials.

When to Choose Scarifying Machines

- Removal of thick coatings, adhesives, or resin layers.

- Deep texturing or roughening of concrete surfaces.

- Renovation of industrial or outdoor floors exposed to wear.

Key Benefits

- Fast, powerful surface processing.

- Adjustable depth for controlled removal.

- Reliable performance under heavy-duty conditions.

Dust Extraction Systems for Safety and Compliance

Every floor processing operation - from grinding to shot blasting - produces fine dust that can impact air quality and worker safety. A dedicated dust extraction system prevents contamination, protects equipment, and ensures clean working environments.

High-efficiency filtration units capture fine particles during continuous operation, helping facilities comply with occupational safety and hygiene standards.

Key Benefits

- Safe, dust-free work environment.

- Improved operator health and visibility.

- Extended equipment lifespan and reduced maintenance.

Partner with Minex for Expert Floor Processing Guidance

Selecting the right floor processing system directly influences performance, durability, and project ROI.

Minex provides more than machinery - we deliver technical guidance to help companies choose the right technology based on material type, surface condition, and production objectives.

Whether you need to remove coatings, prepare concrete floors for epoxy applications, or optimize surface performance, our team ensures that each process step delivers measurable results and long-term reliability.

Schedule a consultation to learn how our floor processing solutions, developed in line with European standards, can support your next industrial or civil project with precision and durability.

Frequently Asked Questions on Industrial Floor Processing

Why is proper floor processing important in industrial facilities?

Proper floor processing is an effective way to ensure coatings and sealants adhere correctly, preventing premature failure and extending the durability of concrete floors under heavy mechanical, chemical, and extreme temperatures stress.

What is the difference between grinding, shot blasting, and scarifying?

- Grinding uses a rotating wheel to produce precise, smooth, and level surfaces, ideal for finishing and surface texture control.

- Shot blasting employs high-velocity steel shot to efficiently prepare large concrete floors, creating adhesion profiles for coatings and enhancing surface roughness.

- Scarifying involves aggressive cutting tools to remove thick coatings or damaged concrete, producing a rough, non-slip surface suitable for heavy-duty applications.

How does floor processing support compliance with hygiene and safety standards?

By removing residues, contaminants, and bacteria, properly processed floors pass stringent regulations like FDA guidelines and EU Regulation 852/2004, helping processing plants maintain a sanitary and safe environment for employees.

Why is dust extraction essential during floor processing?

Operations like grinding, blasting, and scarifying generate fine dust that can harm worker health, reduce visibility, and damage equipment. Dedicated dust extraction systems promote a safe, clean workspace and help facilities pass safety certification requirements.

How should companies choose the right floor processing machine?

Selection depends on surface condition, material type, project needs, and desired finish. Engineers consider whether the job requires precise finishing (grinding), large-scale surface preparation (shot blasting), or heavy material removal (scarifying) to operate efficiently and meet safety and durability features.