Sealants Application & Adhesives Application: Ensuring Strong Bonds and Consistent Results

Table of Contents

- Sealants & Adhesives in Industrial Applications: Ensuring Accuracy & Efficiency

- Core Application Technologies

- Two-Component Systems

- Risk Management in Sealants & Adhesives Application

- Benefits and Strategic Importance

- Application Methods & Process Control

- Accuracy and Process Reliability

- Industry Standards & Best Practices

- Key Industrial Applications

- Industrial, Manufacturing & Processing

- Assembly & Manufacturing

- Glazing & Window Production

- Why Precision Application Matters

- Partner with Minex for Expert Sealants & Adhesives Solutions

Introduction to Dispensing Systems

Modern dispensing systems are engineered to deliver adhesives, sealants, and coatings with accuracy and efficiency in demanding industrial environments. From automotive and aerospace to packaging, assembly, and construction, they give engineers the ability to maintain consistent quality while minimizing waste.

At the heart of many solutions is the meter mix dispense system. These machines combine two or more components in exact ratios, then deliver them precisely to the point of use. Supported by dispensing valves, pumps, and controllers, this type of dispense equipment ensures stability in industrial operations and makes repeatable results easier to achieve.

Sealants & Adhesives in Industrial Applications: Ensuring Accuracy & Efficiency

Sealants application and adhesive bonding are now integral to modern manufacturing. Accurate proportioning and reliable control of materials are required to guarantee strong bonds and durable products. For procurement teams, selecting the right dispensing equipment is the difference between long-term reliability and costly rework.

By aligning dispensing technology with industrial requirements, manufacturers can improve efficiency, protect product integrity, and maintain consistent output across production lines. These systems are not only tools but strategic solutions that support quality, repeatability, and long-term success. Regular operator training and calibration programs further reinforce reliability, ensuring staff can maintain equipment to its designed performance levels and prevent process variability.

Core Application Technologies

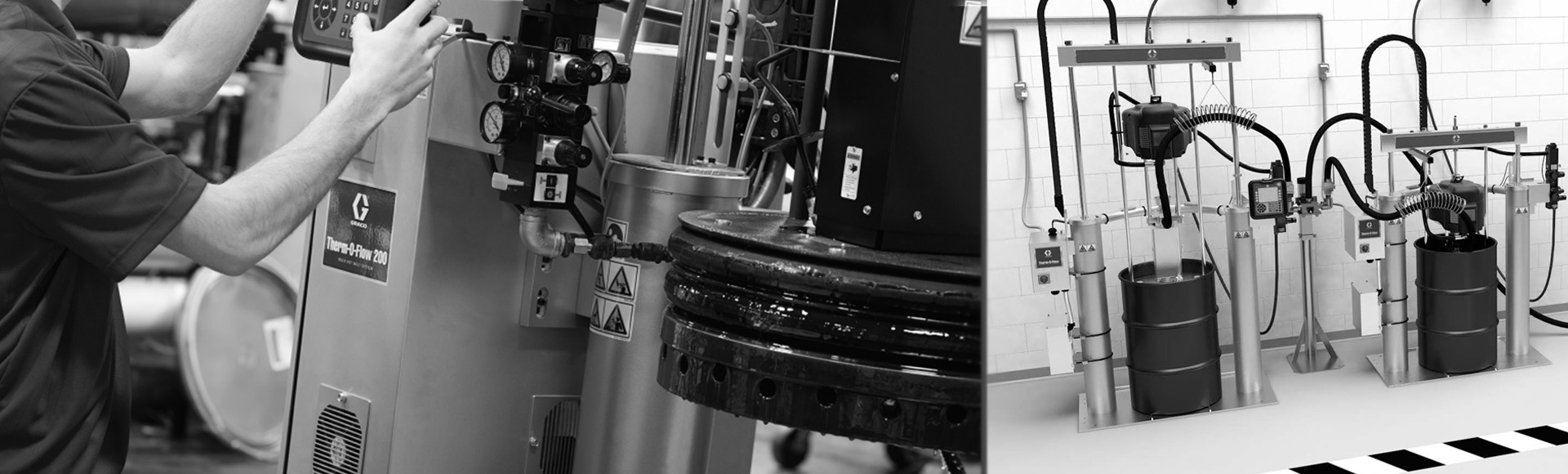

Minex offers a full line of industrial dispensing systems designed to handle a wide variety of applications. Each solution maintains precise control of flow, ratios, and material delivery.

- Meter, Mix & Dispense Systems – Central to adhesive and sealant application, these systems provide accurate measurement and mixing, ensuring that multi-component systems meet production requirements.

- Bulk Supply Systems – Built for high-volume adhesive handling, these systems maintain uninterrupted delivery and stable operation in heavy-duty manufacturing.

- Precision Proportioning Systems – Designed for applications such as glazing, these systems maintain exact adhesive ratios and consistent flow, ensuring sealing integrity and product quality.

Together, these technologies form the backbone of industrial bonding and sealing operations, ensuring accuracy, reliability, and process efficiency. Preventive maintenance programs and continuous equipment monitoring further support stable output and extend operational life.

Two-Component Systems

Two component systems play a decisive role where structural integrity is critical. By mixing separate components such as resin and hardener in controlled ratios, these systems guarantee strong and durable results.

They are widely used across aerospace, automotive, packaging, and construction industries. Their advantage lies in performing the mix and dispense process in one step, ensuring accuracy and reducing the possibility of rework. This makes them an ideal solution for epoxy, polyurethanes, acrylics, and silicones where curing and adhesion must be carefully controlled.

Risk Management in Sealants & Adhesives Application

To avoid premature failures, companies must protect against variability with risk control measures such as:

- Regular calibration and performance verification of dispensing systems.

- Operator training and adherence to standard operating procedures.

- Preventive maintenance schedules tailored to material type and system load.

- Environmental monitoring of humidity and temperature.

By integrating these practices into operational planning, manufacturers strengthen quality assurance and maintain dependable application performance across production environments.

Benefits and Strategic Importance

- Quality & Reliability – Bonds hold under high stress, ensuring long-term performance.

- Process Optimization – Accurate meter mix solutions reduce waste and optimize material use.

- Operational Efficiency – Equipment built for industrial use reduces downtime and increases throughput.

- Cost Control – Stable proportioning prevents over-application and costly rework.

- Repeatability – Consistent patterns ensure that adhesives and sealants are applied within strict specifications.

- Customer Confidence – High-quality output enhances reputation and trust among customers.

Application Methods & Process Control

Effective sealant and adhesive bonding depends on more than equipment alone. Application methods must be adapted to the product and material - whether beads, dots, or spray coatings. Modern dispensing systems can be configured to deliver these patterns with precision, regardless of operator or shift.

Integration with monitoring technologies ensures that process parameters are maintained, providing traceability and additional information for quality assurance. This makes it possible to maintain uniform application across entire production lines.

Accuracy and Process Reliability

The performance of adhesives and sealants is influenced by surface preparation, viscosity, and curing conditions. Variations in these parameters can compromise quality and durability. Advanced dispensing equipment regulates temperature, pressure, and flow in real time, ensuring optimal results.

This level of control helps protect against misproportioning, incomplete curing, or weak bonds, and supports durable products that meet the reliability standards of transportation, aerospace, and other demanding industries.

Industry Standards & Best Practices

Compliance with ISO, ASTM, and EN standards ensures that dispensing processes for sealants and adhesives remain accurate, repeatable, and accepted worldwide. These frameworks define testing methods, durability evaluation, and safety practices, ensuring that every process is aligned with global industry benchmarks.

Key Industrial Applications

Industrial, Manufacturing & Processing

In aerospace, automotive, packaging, and sanitary industries, fluid handling is critical. Meter mix systems control mixing and dispensing for continuous processes such as spraying, bonding, and sealing.

Assembly & Manufacturing

Assembly operations rely on consistent adhesive application for bonding and sealing. High-volume production benefits from bulk supply machines, while meter mix dispense systems deliver accurate ratios in precision tasks such as potting and encapsulation.

Glazing & Window Production

In glazing, uniform sealant application is vital. Precision proportioning systems ensure that component ratios are maintained, preventing leaks and improving efficiency.

Why Precision Application Matters

Although adhesives and sealants make up a small portion of material costs, their correct application has an outsized impact on safety and quality. Poor application can lead to weak joints, leaks, or failure, while accurate dispensing systems ensure reliability and durable products.

For procurement managers, the decision to choose the right dispensing equipment is about ensuring compliance, efficiency, and long-term success - not just reducing costs.

Partner with Minex for Expert Sealants & Adhesives Solutions

At Minex, we support engineers, operators, and procurement managers with a full line of dispensing solutions for industrial bonding, sealing, and encapsulation. From bulk supply to meter mix dispense equipment, our technologies are designed to handle a wide variety of applications with accuracy and efficiency.

Contact us today for additional information, technical assistance, or to schedule a consultation with our team.

Frequently Asked Questions on Sealants & Adhesives Application

What is the main advantage of using meter mix and dispense systems for adhesives?

Meter mix and dispense systems ensure that multi-component materials like epoxies or polyurethanes are mixed in the exact ratio before application. This guarantees bond strength, prevents incomplete curing, reduces rework caused by inaccurate manual mixing, and improves overall process efficiency in sealants application.

When should I choose bulk supply systems over precision proportioning systems?

- Bulk supply systems are ideal for high-volume, continuous operations such as automotive assembly or large-scale packaging, where uninterrupted flow and material supply are critical.

- Precision proportioning systems are designed for applications like glazing and window production, where maintaining exact sealant ratios is important to prevent leaks and ensure structural integrity.

How do two-component dispensing systems improve reliability in critical applications?

Two-component systems mix and dispense materials such as resin and hardener in a single, precise step. This eliminates ratio errors, ensures consistent curing, and produces stronger, longer-lasting bonds - essential in industries like aerospace, automotive, and construction where product reliability and safety are paramount.

What factors influence the accuracy of adhesive and sealant application?

Key variables include material viscosity, temperature, pressure, and surface preparation. Advanced dispensing equipment regulates these parameters in real time, maintaining stable flow and ensuring consistent, high-quality results across shifts and production batches.

How does automation reduce risks in sealants and adhesives application?

Automation minimizes variability caused by manual application. Integrated monitoring systems provide traceability, alert operators to deviations, and enable preventive maintenance scheduling - supporting compliance with industry standards such as ISO, ASTM, and EN for reliable sealants application.

What are common failure risks in adhesive bonding, and how can they be prevented?

Failures often result from poor ratio control, contaminated or unclean surfaces, improper curing, or operator error. Preventive measures include using calibrated, durable dispensing equipment, environmental monitoring of humidity and temperature, and comprehensive operator training to ensure process consistency.

How should procurement teams evaluate ROI for dispensing systems?

ROI should be assessed not only by equipment cost but also by reduced rework, less material waste, increased throughput, and extended product life. Selecting the right dispensing system ensures durable, compliant bonds while lowering total production costs and improving operational efficiency.