Industrial Metalworking: Ensuring Guaranteed Quality with CNC Process Control

Table of Contents

- Industrial Metalworking: A Strategic Foundation

- Core CNC Technologies for Metalworking

- CNC Lathes

- CNC Milling Machines

- CNC Machining Centres

- Strategic Benefits

- Metalworking Techniques and Tools

- Key Industrial Applications

- Manufacturing of Single Pieces & Small Series

- Plates, Profiles & Pipes Processing

- Metalworking Safety and Future

- Partner with Minex for Expert CNC Solutions

Industrial Metalworking: A Strategic Foundation

Metalworking is a strategic foundation at the heart of the manufacturing industry, shaping the quality and efficiency of everything from custom parts to large production runs. Modern factories demand high-precision machining processes that minimize material waste, deliver very fine finishes, and ensure consistent quality.

This necessity drives the shift to CNC machines, where pre-programmed software guides precise tool paths and axis movement. This automation allows engineers, CNC machinists, and operators to efficiently produce complex shapes and finished parts at high speed, while improving safety and reducing downtime. The finished part is the completed outcome of the machining process, meeting all specifications and ready for use or further handling.

Minex specializes in three advanced categories of CNC technology for diverse metalworking needs: CNC Lathes, CNC Milling Machines / CNC Mills, and CNC Machining Centres.

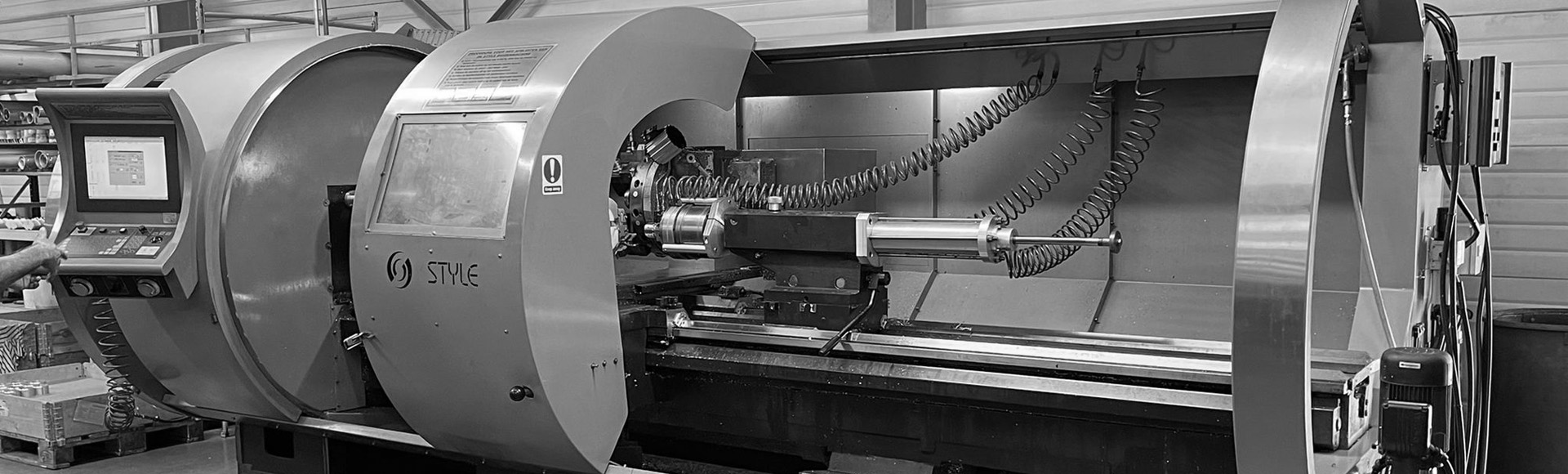

CNC Lathes

CNC Lathes are turning machines that are specifically specialized in the manufacturing of single pieces and small series.

- Primary Purpose: Ideal for turning operations, shafts, and cylindrical components.

- Design Advantage: Characterized by structural stability due to their unique design and stable cast iron frame.

- Benefits: They offer excellent speed, flexibility, and are described as very user-friendly.

CNC Milling Machines

CNC Milling Machines are cutting machines known as the most versatile milling machine for single pieces and small series.

- Primary Purpose: They excel at quickly producing complicated products by streamlining the process and making them less complicated. They are highly effective for creating complex geometries.

- Design Advantage: Feature a large reach and a spacious work table.

- Advice: Allows the operator to work fast, smart and easy.

CNC Machining Centres

CNC Machining Centres are multipurpose solutions listed as a primary product category under Metal Working.

- Primary Purpose: They are used for general high-quality manufacturing/versatile metal removal tasks.

- Design Advantage: These centres are designed to perform multiple operations in a single setup, offering high efficiency for production work.

- Application: Excellent for customers requiring high-quality manufacturing solutions

Strategic Benefits

The key advantages of modern CNC machines stem from the integration of robust hardware and intelligent software:

- Intuitive Control System: The Control System (applicable to all) is used to allow the operator to work with a fully intuitive CNC control without G-code knowledge.

- Programming Efficiency: The Programming Solution eliminates the necessity of complex G-code knowledge, allowing operators to focus on production.

- Accessible Operation: The control provides an accessible manipulation for the novice operator with extensive functionalities for the experienced operator.

- Hardware Stability: Structural Stability (Lathes) is characterized by a unique design and stable cast iron frame.

- Milling Specific Benefit: Each milling machine has a large reach and a spacious work table.

Metalworking Techniques and Tools

Modern metalworking relies on a range of techniques to transform raw materials into objects, parts, and structures. The three primary categories are forming, cutting, and joining processes. Forming processes reshape metal without removing material, using methods such as bending, rolling, and forging. Cutting processes, on the other hand, remove material to create precise parts and complex geometries. This includes operations like milling, drilling, and turning—tasks where CNC machines, especially CNC lathes and CNC milling machines, excel thanks to their high precision and efficient material removal. Joining processes, such as welding and brazing, are essential for combining multiple metal components.

The success of any metalworking project depends on selecting the right tools and equipment. Traditional tools like milling machines, drill presses, and angle grinders remain essential, but the rise of CNC machines has transformed the landscape. Cutting tools, including end mills and drill bits, are critical for operations like face milling and shoulder milling, while abrasive tools help achieve very fine finishes.

Key Industrial Applications

Manufacturing of Single Pieces & Small Series

Customised production, prototypes, and small batches rely on speed and flexibility.

- Recommended Technology: CNC Lathes and CNC Milling Machines.

- Benefit: Speed, flexibility, and being very user-friendly.

Plates, Profiles & Pipes Processing

General processing tasks related to these materials demand adaptability and scalable options.

- Recommended Technology: CNC Lathes, CNC Milling Machines, and CNC Machining Centers are all used within this product context.

- Benefit: Provides an accessible control for the novice operator with extensive functionalities for the experienced operator.

Metalworking Safety

Safety is paramount in any metalworking environment, given the potential hazards associated with machines and sharp edges. Metalworkers must always wear appropriate protective gear, including safety glasses, gloves, and earplugs. Proper training on the operation and maintenance of CNC machines is essential to prevent accidents.

Metalworking Future

The future of metalworking is being shaped by rapid advancements in CNC technology and automation. The integration of Computer Aided Design (CAD) and CAM software is streamlining the entire machining process, from initial concept to finished product. Emerging materials and techniques like 3D printing and robotics are opening up innovative manufacturing pathways. To stay competitive, metalworkers must embrace these technological changes.

Partner with Minex for Expert CNC Solutions

Every engineer and procurement manager recognizes the strategic importance of selecting the right CNC technology. The correct choice safeguards productivity and quality.

Minex provides expert guidance across CNC Lathes, CNC Milling Machines, and CNC Machining Centres. With our support, you can confidently implement advanced machines that deliver structural integrity, efficiency, and measurable ROI.

Contact Minex to discuss your next metalworking project and discover the CNC solution best suited to your facility.

Frequently Asked Questions on Industrial Metalworking with CNC

What are the main differences between CNC lathes, milling machines, and machining centres?

- CNC Lathes specialize in turning operations, ideal for producing cylindrical metal objects such as shafts and bushings. They offer excellent speed, flexibility, and structural stability, often featuring fewer axes than milling machines.

- CNC Milling Machines excel at cutting metals and other materials with high precision, thanks to their advanced machine tool paths and large work tables. They are versatile for creating complex shapes using various cutting tools.

- CNC Machining Centres integrate multiple processes—milling, drilling, boring, tapping—into a single setup, improving efficiency for mass production and reducing manual control interventions.

When should a manufacturer invest in a CNC machining centre instead of standalone lathes or mills?

Machining centres are best suited for advanced jobs requiring multiple operations on a single part, minimizing setup times and improving the structural integrity of finished parts. They are ideal for facilities aiming for large scale structures production with high precision and repeatability.

How does CNC process control improve efficiency for operators with different skill levels?

Modern CNC machines work with intuitive control systems and computer programming that reduce the need for manual control and complex G-code knowledge. This allows CNC operators, from novices to experts, to manage tool movement precisely, ensuring consistent quality and safety.

How do CNC machines help reduce material waste and improve ROI?

By controlling tool paths and axis movement with high precision, CNC machines minimize material waste during cutting processes. This is especially beneficial when working with expensive materials like precious metals or sheet metal, directly enhancing return on investment.

What role do CNC machines play in prototype development and small batch production?

CNC lathes and milling machines provide flexibility for rapid prototyping and small batch runs. Their ability to quickly adapt to design changes through CNC programming enables efficient production of custom parts and medical devices with desired shapes.

What safety practices should be prioritised in CNC metalworking environments?

Operators must use protective gear such as safety glasses, gloves, and hearing protection. Regular maintenance of automated equipment, proper training on emergency stops, and understanding machine tool components are essential to prevent accidents.

How is CNC technology evolving to meet future industrial demands?

The integration of CAD/CAM software with CNC machines enhances programming efficiency and precision. Emerging technologies like CNC plasma cutters, live tooling, and hybrid additive-subtractive processes are expanding capabilities for cutting metals and joining materials in complex applications.