Arc Spraying - производствен ремонт на автомобилни сглобки

02.08.2016

Car bodies are prone to minor damage to the anti-corrosion protection system both during the production process and during handling and assembly operations. Thermal spray metallization is a quick, safe, and economical solution for correcting these errors.

Typical situations requiring repairs before applying paint

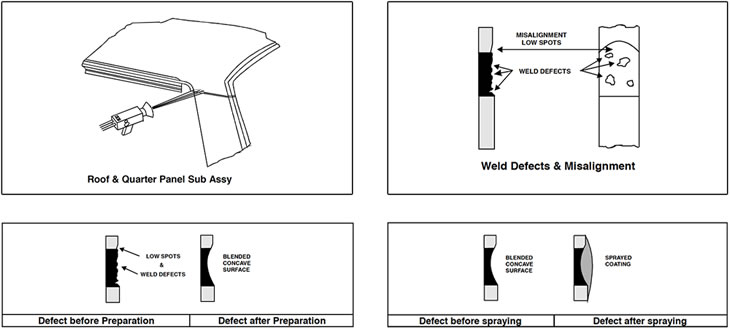

Car roofs and upper body parts - Welding and alignment defects

These subassemblies are created by manually welding the connections between them. The weld area is touched up by grinding. For this reason, certain portions of the surface present imperfections that need correcting.

Doors and lower parts of car bodies

Doors and adjacent body components are relatively vulnerable in the assembly process due to the thin sheet metal from which they are made. Damage to these components from sequential pressing and handling is inevitable, which is why their rectification is imminent.

The most common types of faults refer to:

- unwanted deformation of a surface due to overheating;

- the appearance of cracks on the surface as a result of hitting it;

- minor breaks caused by the lack of elasticity of the material at certain points;

- lack of uniformity at joints, which especially causes problems when closing doors.

Classic repair methods

Where possible, manual welding techniques are usually used for repairing these faults. This method, already standardized in recent years, has proven to be relatively satisfactory, although costly in terms of manpower involved, the time required, and the lack of automation, which is becoming an increasingly pressing need.

Deficiencies that can occur after the painting process

Imperfections generated by the classic welding process used basically for surface leveling can generate secondary effects of gas insertion at the surface level, which, over time, lead to the appearance of roughness on the surface.

Thermal spray metallization method

The specific procedure requires:

- surface preparation by blasting – SB 750;

- application of zinc or aluminum by the metallization process;

- smoothing of the deposit to level the surface;

- ensuring that the treated surface is brought back to the desired hardness area, properly cleaned, adequately dried, and perfectly prepared for subsequent painting operations.